Ultrasonic Washing – commonly functions improved for intricate sections for instance filling needles since it will involve a tank equipped with ultrasonic transducers to induce cavitation

The company’s adjust Handle technique must incorporate a bit for your analysis in the effects of cleaning validation by a selected subject matter pro (SME) inside the Corporation.

The routine or periodic sampling approach should allow the manufacturer to observe important cleaning attributes while minimally impacting the cleaning turnaround time. For instance, particular analytical methods for instance higher-efficiency liquid chromatography (HPLC) are most well-liked for validation applications, whereas nonspecific methods which include conductivity, titration, or complete organic and natural carbon (TOC) could be extra suitable for schedule use because of their fast response periods.

Cleanability also will take into account the sur-face-residue conversation (such as residue conditions as well as floor style) And the way cleaning brokers or cleaning mechanisms split that conversation.nine Solubility is frequently limited to the active component and might not be consultant of the whole method soil, particularly when cleaning is performed employing a cleaning agent other than drinking water. For these good reasons, grouping strategies missing scientific info to assistance cleanability should be reassessed to provide improved justifications in the choice of worst-situation soils.

System capability compares the output of the process to your specification limitations by making use of ability indices. The comparison is produced by forming the ratio in the spread between system technical specs as well as the unfold of process values, as measured by a few or 6 moments the procedure common deviation models.

Verify visually no stagnant water shall be permitted to continue being from the products subsequent to cleaning operation.

While this document is about cleaning validation, the next references on impurities from the Intercontinental Council for Harmonisation (ICH) can also be useful:

This knowledge is necessary to help decide which cleaning brokers, solvents and cleaning method parameters can be most correct. It should be pointed out that by-solutions can also be created via conversation With all the cleaning brokers and solvents.

Get in touch with Member Expert services at question@ispe.org For more info or When you've got questions about your membership position or this lower price program. Special discounts don't utilize to Techstreet document downloads.

Should the product is worst-situation then cleaning validation need to be performed Using the very same gear chain.

An effective treatment for keeping stainless-steel surfaces in a very passivated point out and preventing check here corrosion needs a cautious balance of numerous factors, which includes:

Biotechnology cleaning processes usually entail situations that result in protein molecules to denature or degrade so residual measurements tend to be performed employing a non-certain test method such as TOC.

If no cleaning validation needed or not completed on the subsequent worst-scenario inside 03 decades then revalidation shall be carried out on present worst within the frequency of 03 read more years,

This template is utilized to complete the process validation protocol by reporting the verification of the devices/system last layout towards the person, purposeful, and/or design and style technical specs. Effortlessly identify vital tools components, utilities offer, and environmental needs.

Michael Oliver Then & Now!

Michael Oliver Then & Now! Jenna Jameson Then & Now!

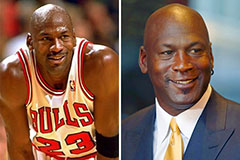

Jenna Jameson Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now!